Home / Our Stories /

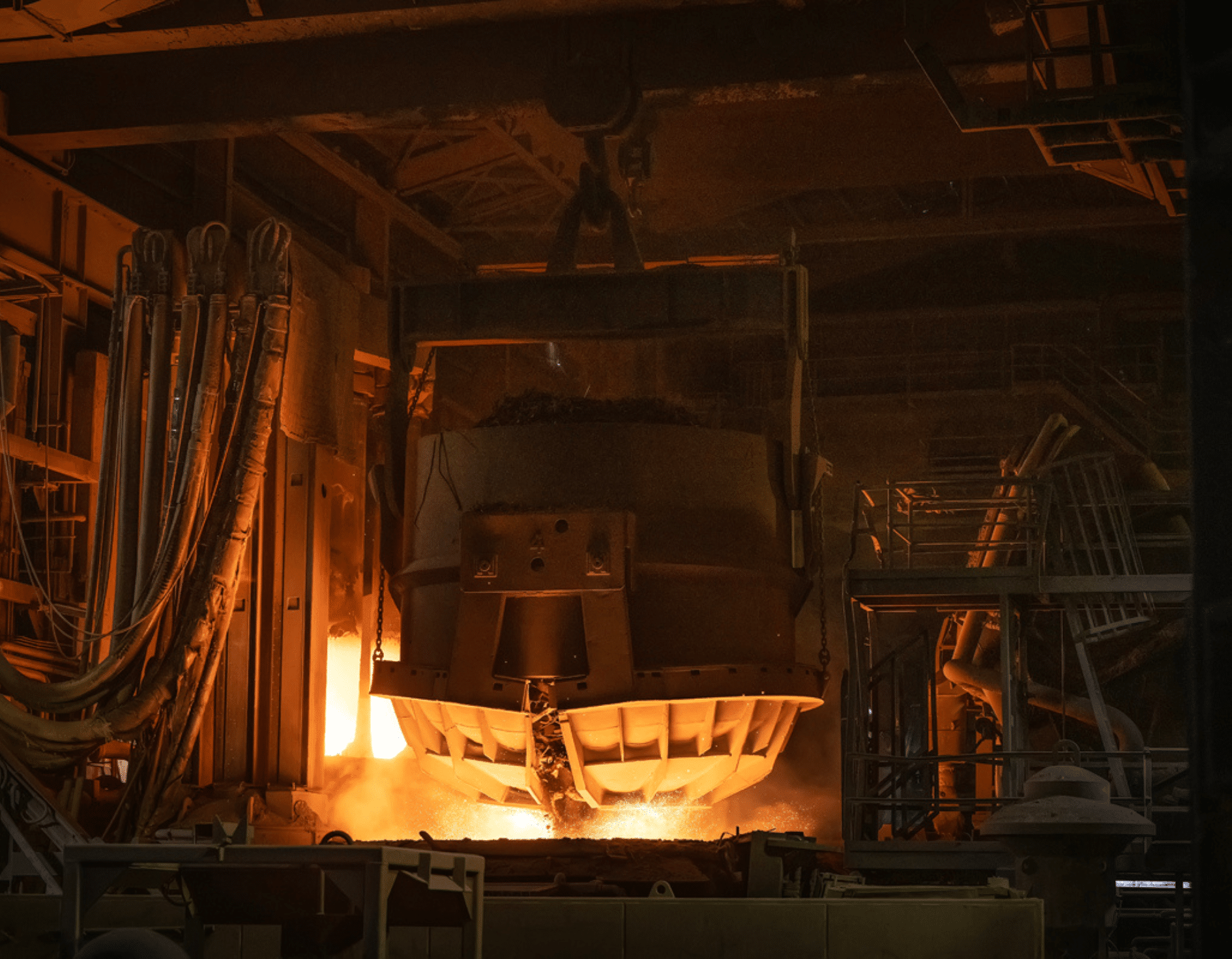

How InfraBuild’s Electric Arc Furnaces Support a More Sustainable Future

3 March 2025

InfraBuild is the only Australian steelmaker using electric arc furnaces (EAF). What does that mean for the environment and the industry?

Lower emissions, higher efficiency

Traditional steelmaking relies on iron ore and coal, which produce high carbon emissions. EAFs, on the other hand, primarily use scrap metal. This reduces reliance on raw materials, lowers greenhouse gas emissions, and improves energy efficiency.

A circular economy in action

InfraBuild’s EAFs play a key role in recycling, turning scrap metal into quality steel products. This helps reduce waste, conserve natural resources, and keep steel in use rather than sending it to landfill. In Australia, InfraBuild recycles approximately 1.4 million tonnes of scrap per year, demonstrating the significant role of EAFs in sustainable resource management.

The future of lower-emission steelmaking

As industries work towards net-zero emissions, InfraBuild is focused on reducing the carbon footprint of steel production.

“Our investment in electric arc furnace technology is all about making steel in a smarter, lower-emission way,” says Hercules Van der Merwe, Head of Victorian Rod and Bar Manufacturing at InfraBuild. “By focusing on efficiency and recycling, we’re cutting emissions and producing top-quality steel that meets global sustainability goals.”

InfraBuild is proud to be the only EAF steel producer in Australia, leading the way in lower-emission steelmaking.

Please contact us for any feedback or media enquiries about this content.

Subscribe to the

InfraBuild newsletter

Receive regular updates on news, case studies as well as the latest products and services.